Product Category

Product Category

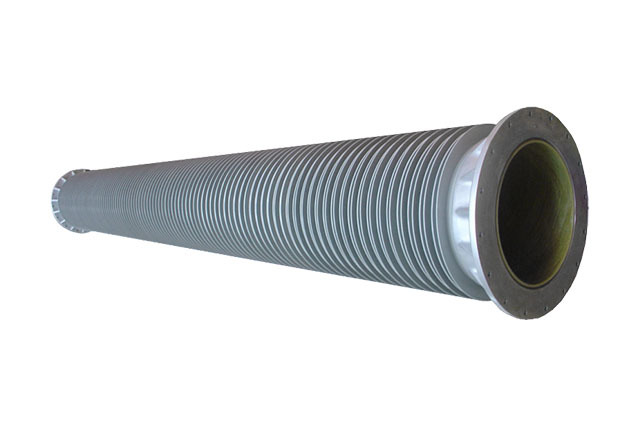

Hollow Composite Insulator

Product Introduction

Hollow Composite Insulator is a class-A component of external insulation of high-voltage electrical products consisting of epoxy glass fiber winding pipe, organic composite sheds and end metal flange attachment. Hollow Composite Insulators are mainly used for circuit breakers, load switches, disconnectors, earthing switches, current transformers and power transformers, bushings, cable terminations and external insulation support of arresters.

Advantages of Hollow Composite Insulator:

1. It has a stable and reliable mechanical performance, no dangerous accidents happen such as breaks and explosions, it can protect better other operating equipment.

Epoxy fiberglass wound tube has excellent impact resistance, which can effectively prevent flying debris from hurting personal injury and damaging other power transmission and transformation equipment, additionally avoid insulator brittleness caused by earthquake.

2. The Hollow Composite Insulator is smaller, lighter in weight, and easier to install and transport.

The weight of the composite insulator is only 1/7-1/3 of porcelain insulator, which is easier for installation, transportation and construction. It can effectively reduce the overall weight of high-voltage electrical appliances.

3. The epoxy glass fiber winding pipe and the end metal flange attachment adopt a mixed sealing structure of interference fit and a multi-layer labyrinth, which better ensure the product has a very reliable sealing performance. The sealing structure can completely avoid electric leakage accident of the high-voltage electrical appliance due to aging and failure of the sealing ring for long-term stress.

4. Excellent weather resistance and surface tracking resistance

The organic composite sheds still has good weather resistance and ozone resistance at the ambient temperature -40 ° C -100 ° C, and the surface tracking resistance can reach TMA 5.0.

5. Hollow Composite Insulator has a unique hydrophobicity and hydrophobicity migration, as well as excellent antifouling property

The unique hydrophobicity and hydrophobic migration make the hollow composite insulator still has reliable anti-fouling flashover performance in wet, dirty, rainy and foggy weather. The properties can effectively avoid pollution flash or wet flash, and make the Hollow Composite Insulator more suitable for use in heavily area dirty or DC transmission and transformation system.

6. The forming process used to produce the Hollow Composite Insulator is reliable. Its production cycle is short and energy consumption is low. It is an environmentally friendly product.

7. Overall performance-cost ratio of the Hollow Composite Insulator is higher than that of porcelain insulator.

Product Display

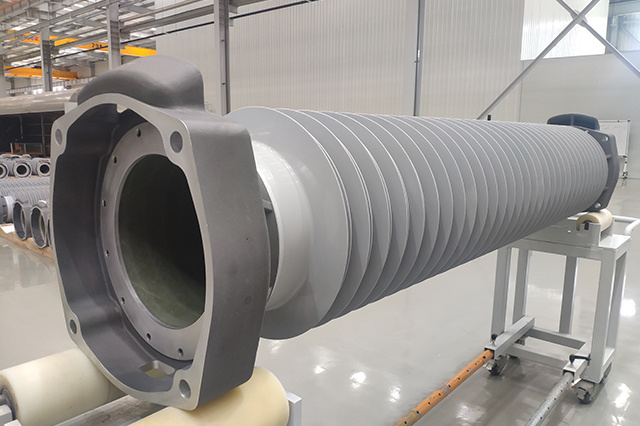

Equipment Display

Bending test

Production workshop

Production workshop

Production workshop

Production workshop

Sealing test

Key word:

Hollow Composite Insulator

Need help?

Let's ask your questions

HERE YOU CAN FIND WHAT YOU WANT

Overseas Marketing Center:

Tel: 0086-02583147312

E-mail: yuwenwen@ld-cn.com

Address: No. 99 Xianxin East Road, NanjingEconomic and Technological Development Zone,Jiangsu Province